MDF Wood Board Production Line Macking Machine

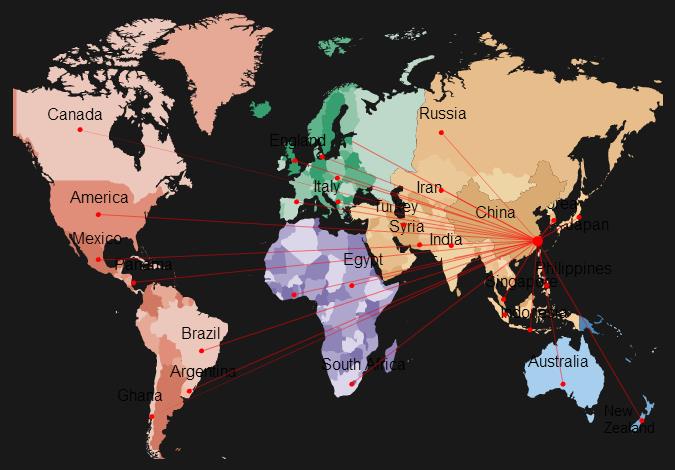

ZST can offer fiberboard production line,second hand fiberboard production line, single machinery and consumption spare parts.

If you are planing to start a business in wood based panel industry, you can follow my steps to see what you should prepare:

1. Large Enough Lumber Storage Area

2.Chipper

To make the lumber become pieces of wood,The serial drum chippers for our company especially supply high quality wood chips in processing of raw material for pulp paper , MDF , OSB , particle board , fuel power plant etc. The raw materials for cutting mainly are log , bamboos , branches , wood slabs etc. Adaptation capacity is from 8~180m³/h , and the users can choose model based on their need.This serial drum chipper is made up of seat, knife rotor, upper and down feeding roller, hydraulic pressure system, and electric control system. The seat adopts high strength steel plate welded and overall elimination stress treatment which proves strength and service life. The in-feed rollers adopt the dismantle structure for easy to replace. The bottom cutter seat uses hydraulic pressure oil cylinder to change bed knife conveniently and fast, meanwhile the cutting roller adopts protective plates structure to extend service life.

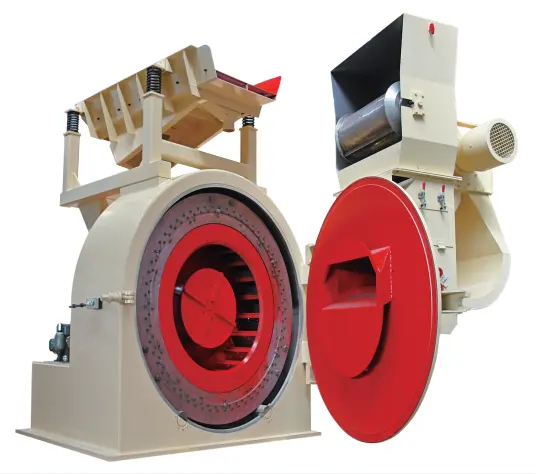

3.Flaker

4.Vibration Screen

5.Dryer

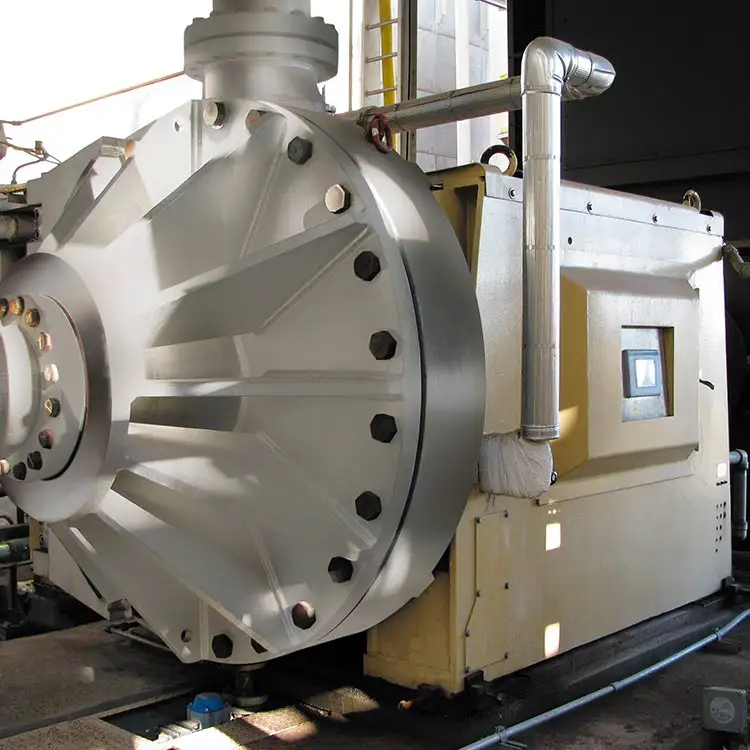

6.Refiner&Defibrator

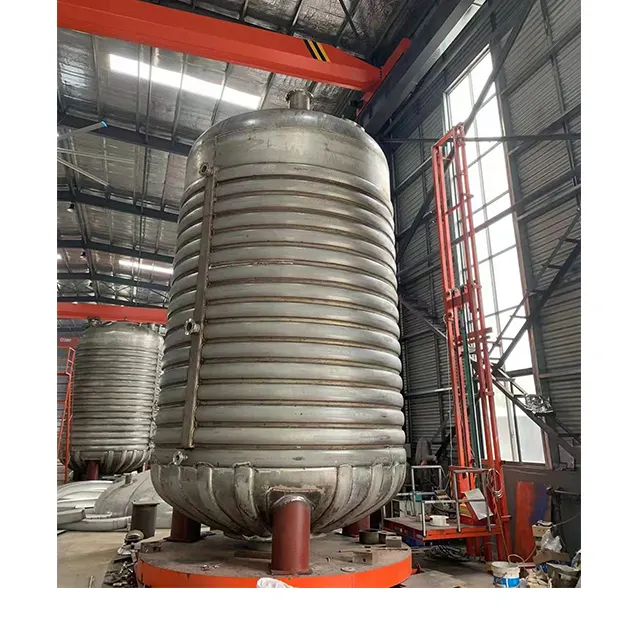

7.Glue Blender

BS series of new ring type glue mixing machine is a new generation of glue mixing equipment successfully developed by researchers based on centrifugal glue mixing machine after years of practice. The equipment is suitable for supporting production lines of wood particleboard, bagasse board, cement particleboard and fiberboard with an annual output of 50,000 m³ to 450,000 m³.

to mix the chemical addictives such as urea formaldehyde glue,melamine formaldehyde glue,etc.

9.Forming Machine

10.Pre-press Machine

11.Hot Press Machine

we can offer multi-layer press machine,continuous press machine.

12.Star Cooler

after the wood panel finished hot press, the temperature of the board is very high, we need use the star cooler to cool down the temperature,the hot wood board will be convey by the conveyor belt.

13.Staker

14.Sanding machine

It also caters to the application of calibrating and polishing metal such as press platen, stainless steel plate and aluminum

plate, and material like PVC, marble.

-Minimum thickness 2 mm

-Adjust thickness by Ball screw which ensures no reverse clearance when grinding to improve sanding precise.

-Eccentric device of contact roller with no clearance after special design ensures the accuracy of sanding thickness, operating

from one side, makes the eccentric volume of contact roller be adjusted from one side or two sides and the operation can be more

humanized.