Do you need to buy E0, E1, E2, or CARB MDF, Particleboard, or Plywood?

Some of the more common materials used to make furniture are MDF, particleboard, and plywood. Although these items may sound familiar, knowing what they are made with could be the difference between following the law and breaking it.

Medium Density Fiberboard (MDF) is one of the most commonly used materials. It is a wood-based sheet material prepared by pressing together wood fibers with a synthetic resin adhesive. MDF is principally composed of softwood, but some brands may contain a considerable percentage of hardwood as well. MDF is very strong, easy to veneer, and commonly used in high-end as well as more economically priced furniture.

Plywood is commonly used in cabinet construction. It is an ideal choice for slightly flexible resources. Plywood is made of wood veneer layers that are laid and pressed together with a synthetic resin adhesive. This sort of construction technique makes it less prone to warp/crack or shrink than solid wood.

Another widely used material is particleboard. Particleboard is a mixture of wood shavings and chips, bound together through resin. Although particleboard is not as strong or aesthetically appealing as MDF or plywood, it costs less and therefore makes it more practical for some applications.

One major process these 3 materials share is they are pressed together using a resin adhesive. It is the level of formaldehyde in the adhesive that will determine if your product is within the boundaries of the law when talking about air quality and emissions, as formaldehyde is considered carcinogenic.

According to International Composite Board Emission Standards (ICBES), there are 3 European formaldehyde classes, namely: E0, E1 and E2. This classification is based on the measurement of formaldehyde emission levels. For instance, E0 is classified as having less than 3 milligrams of formaldehyde out of every 100 grams of the glue used in particleboard and plywood fabrication. E1 and E2, conversely, are classified as having 9 and 30 grams of formaldehyde per 100 grams of glue respectively. All around the world variable certification and labeling schemes are there for such products that can be explicit to formaldehyde release, like that of Californian Air Resources Board (CARB).

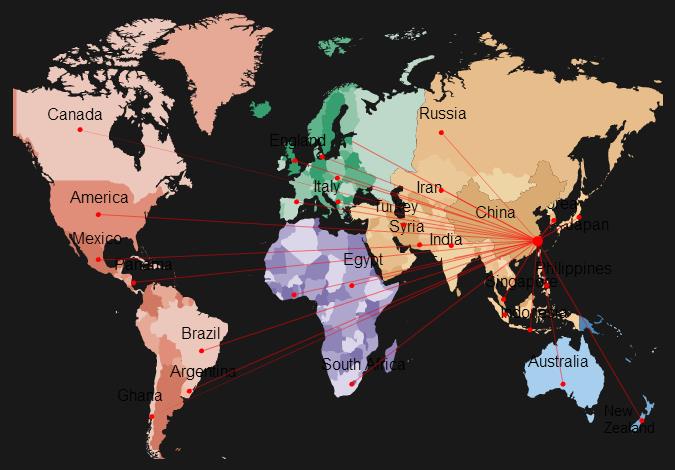

Be sure that when working with suppliers that they adhere to these international standards and those specific to your country both to protect your business and the health of your customers.