Plants for wood-based materials production

Plants for wood-based materials production

Siempelkamp supplies your wood-based panel plant for chipboard, MDF, OSB or even wood fibre insulation panels according to the principle “Everything from one source”, because our unique selling point is the mapping of the entire production process for wood-based panels, starting with wood preparation and size reduction, storage, classification by gravimetric separation or screening technology, pneumatic and mechanical conveying technology, drying technology, a variety of gluing systems, forming and press lines and coating. We can support all production processes with a focus on the safety and efficiency of your wood-based panel production with our in-house expertise in the areas of raw panel handling and automation.

Future-oriented plants for the wood-based panel industry with a sustainable after-sales & service concept

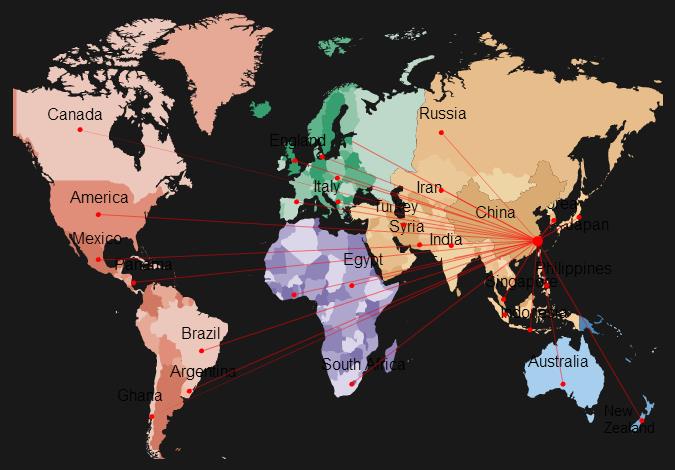

We plan all process-determining machines of your plant and produce them together with the worldwide specialist companies within our group of companies. Upon request, we can include third-party machine technology in our integrated planning concept. We then handle the logistics and supervise the installation and commissioning of the entire plant. After the successful start-up, we provide you with comprehensive after sales & service throughout the entire life cycle of the plant. Our concept ensures that economic plant concepts (plant and process piping concepts) that are fully tailored to your needs are implemented. We accompany customers all over the world on their way to the best wood-based panel for the respective application. Trends and current developments such as resource-saving use of raw materials, alternative raw material concepts (e.g. rice straw, bagasse, bamboo, hemp, oil palm etc.), process optimisation and energy-efficient technologies are one of the focal points of our range of services.

We offer our Siempelkamp complete plant concept for a variety of applications

The widest range of machines and plants for the production of wood-based materials

Providing our partners with complete plant systems is our core competence

The fact that we have sold 320 ContiRoll® concepts makes us the world-market leader for complete plants for the production of woodbased materials.We support customers reliably, efficiently, and individually from the engineering to the after-sales service. All this saves our customers time, costs, resources, and logistics expenditure.